/// THE TEAPOT ///

I recently spent a month up in Scotland on a silversmithing residency (see previous journal for details) and while I was there I used my time to create my most ambitious design to date, a teapot.

Why did I choose a teapot? These used to be made regularly, and as part of a silversmithing apprenticeship as they are bloody difficult to make (that’s the technical term) because you need to be skilled, patient, and precise. I knew I wanted to give it a good go so having a month with no other distractions or commitments seemed like the perfect time.

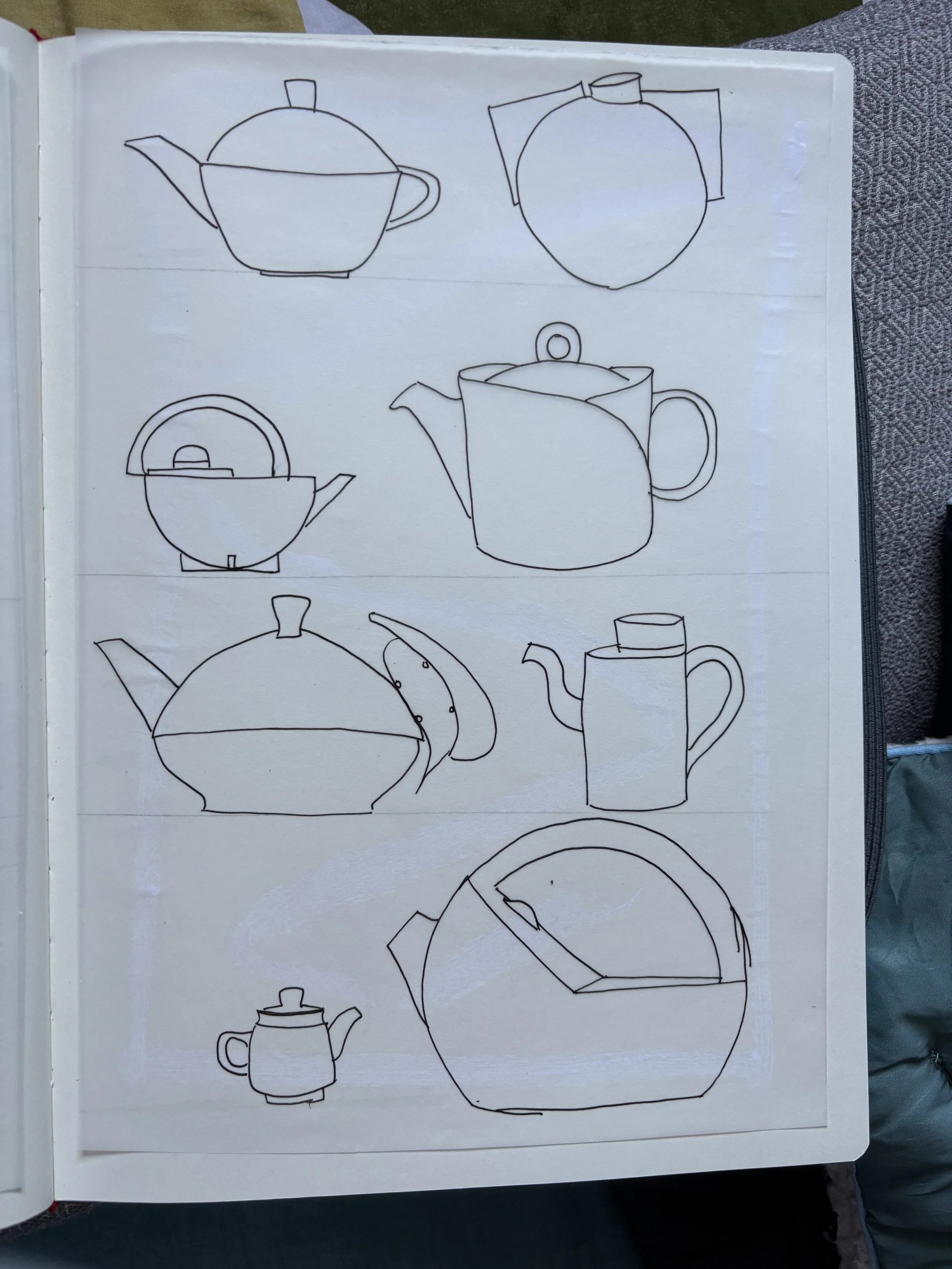

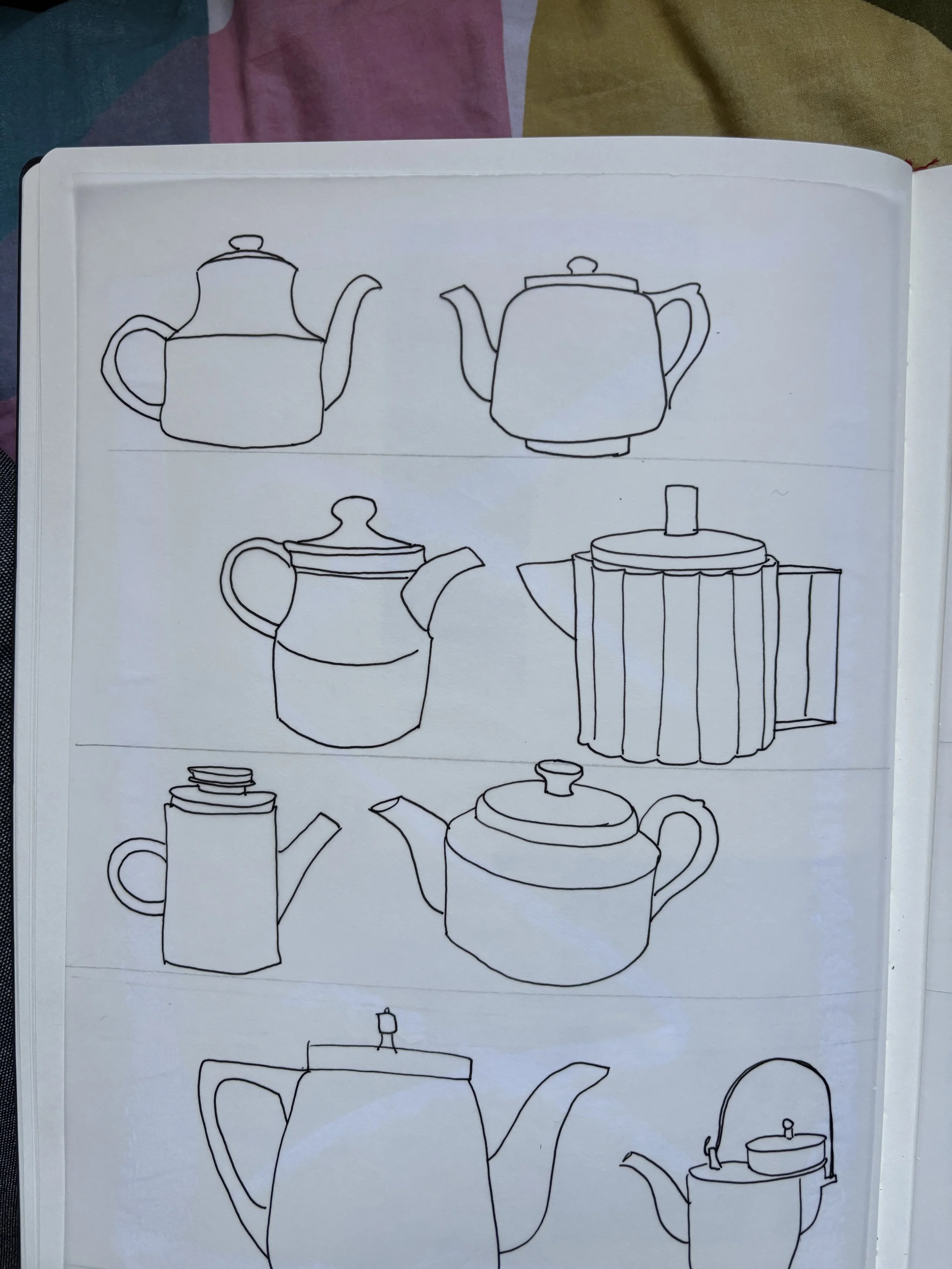

Before the residency began I spent a couple of months researching teapots - ones I liked, ones I didn’t, what makes a good teapot, gathering information of lots on the market like what size, spout placement, handle placement etc.

I had a good idea in mind of the kind of shape I wanted my teapot to be but wasn’t sure of the smaller details. So I started sketching the shape with different spouts and handles but nothing really appealed to me and I started to get a little disheartened. Then I had a brainwave - why am I trying to design a different style of spout when I already know what I love and what works - a curved arc spout like that I have used on my jug designs in the past. And suddenly I fell in love with my design and wanted to work on it again.

The original design before changing the spout

I knew I wanted my handle to be comfortable to use, it is really important to me with all my designs that form and function are equal. My creations work as well in a utilitarian sense just as well as they are pleasing to look at. So the spout and the handle both need to be spot on. The handle, and the knob on the top of the lid, will both be made out of a dark wood which will contrast really well against the silver. These are made using a material different to the metal of the teapot because metal is an excellent heat conductor, which is great for the body but would mean the handle would be too hot to hold without scolding yourself. So that won’t get a tick in the functional box I like to tick! Other considerations in making a teapot are spout placement, if it starts too low down on the body the water naturally rises up it when the teapot isn’t in use, size of holes in the spout grid, placement of the holes, placement of the handle, weight distribution for ease of lifting and pouring, the list goes on.

I made the teapot in brass, and I made two of them. The reason I am making in a base metal rather than silver is quite simply due to cost; the price of precious metal has risen so much in the past few years that I just can’t afford to spend that much on an item I am not sure will sell immediately to reimburse me. So the plan is to make in another metal, then get silver plated. Brass is notoriously difficult to solder but I chose it over copper as copper can be quite a flexible metal and I needed something which would keep nice and rigid, helping the shape of the teapot to stay true. The finished teapot will be photographed, the silver plated teapot will be for sale, and the photos will help to promote it and if anyone would like to commission one to be made in silver (the goal).

I am making two because I’ve never made one before, so it is very much learning on the job so I would rather make two so if anything goes wrong with any of the steps I still have another one to get it right.

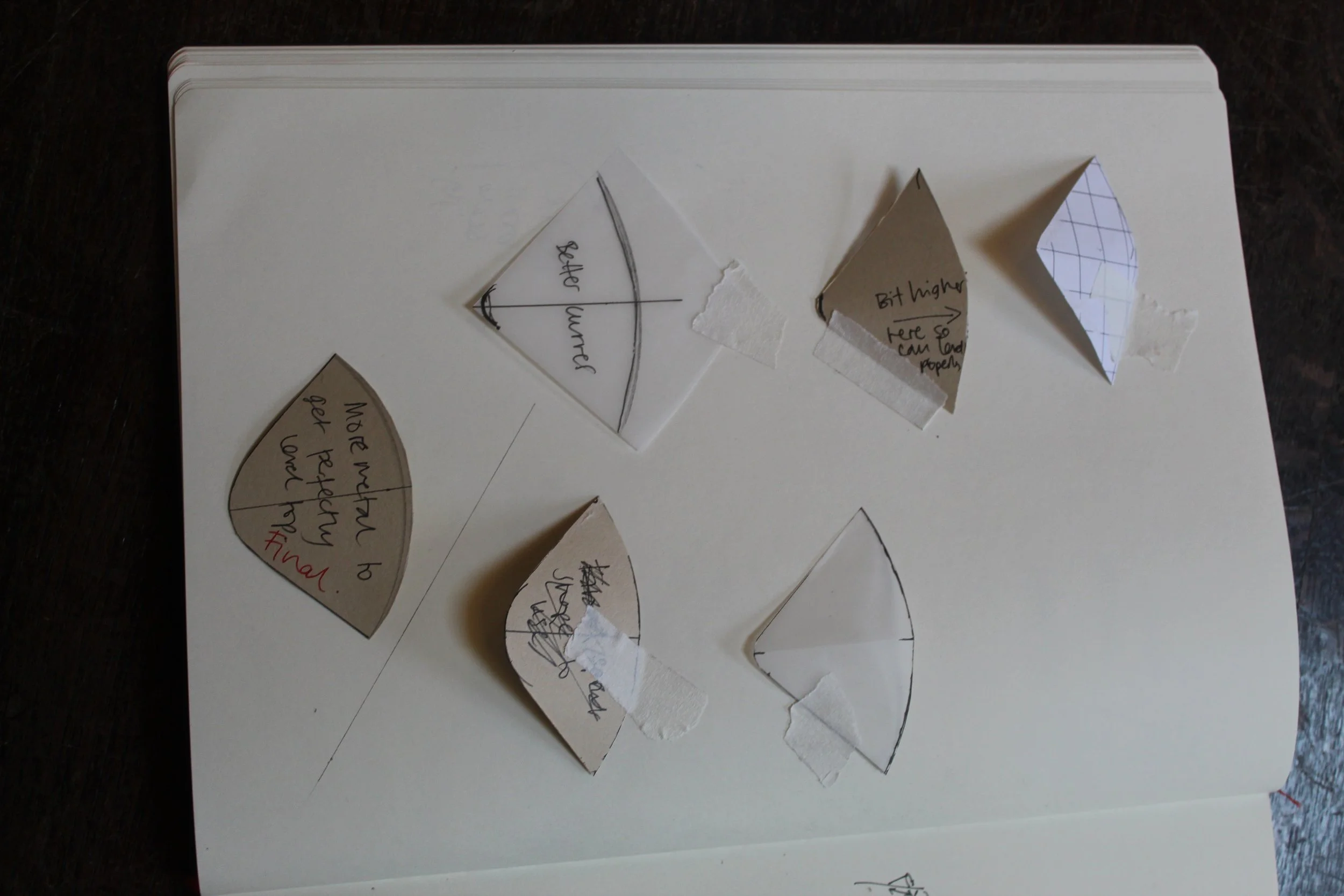

Once I finalised the design I made it in card so I could double check the scale and proportions as I want to get these perfect before going ahead in metal.

I decided to get the two components for the body “spun”, this is where a spinner, in this case Warren Martin, spins the metal on a lathe, manipulating it into the required shape. The reasons I decided to get these spun were two-fold - firstly there is less material waste when creating a truncated cone from spinning that making it from a flat sheet when you use forming and soldering to create it. And secondly, I have made many a truncated cone, I know it is something I can do so I didn’t want to waste my precious marchmont studio time on skills I already have. I wanted to use that time learning the new skills of making the teapot.

I spent the first week of the residency finessing the fittings for the handle. It was like Goldilocks porridge, the first ones were too narrow, the second ones too chunky, and the third ones just right. I felt grateful of having the luxury of uninterrupted time to spend on getting that element just right.

Once I nailed those it was time to move onto the spout. Again, made in cardboard first to double check size and proportions before making in metal.

It then took what felt like YEARS (being very dramatic) to file the spout and the handle fittings to the exact right curve to fit perfectly against the body of the teapot, so there were be no gaps when they were soldered on. It took a few days of working on them on and off as they are such awkward shapes to hold and it was brutal on my hands.

Then I drilled the holes for the spout grid, the holes in which the tea flows through and down into the spout.

Then began the soldering. This was the part I was most apprehensive about. Because of the sheer size of it, because of using an unfamiliar torch, because of the issue of the brass possibly warping shape so they components no longer fitted together, and also the possibility of the components shifting out of place just as the solder ran and sticks them together at the wrong angle.

First up was soldering the internal rim of the teapot to the top part of the body.

Followed by soldering a bezel to the lid, so it would fit inside the teapot nice and snug.

Then came the part I was most worried about, soldering the top of the body to the bottom of the body. These took a while to prepare for the soldering as I needed to do everything I could to prevent either piece from warping, or shifting, while making sure the solder flowed evenly around the entire circumference as there can be no holes in a teapot!

Nerve-racking, but done! Then onto soldering the spout in place, then the handle fittings. Only when these were all done did I allow myself to breathe a sight of relief and give myself a pat on the back because I had achieved something I never truly believed I would. And all by myself too! I was so very proud.

Now I am back in Norfolk there is still some work to do on the teapot, they still look a bit messy so I need to tidy the solder up, smooth everything over then make the handle and knob. I knew that I wouldn’t get time to work on that immediately so it will be a few weeks but I’m fine with that. I’m very happy that I have actually made two teapots, they pour well, they don’t leak, I love the design and I still pinch myself and think I did that, me, on my own!

Once the teapots have been completely finished I will post photos, but for now enjoy this artist's interpretation of how it will look when finished!